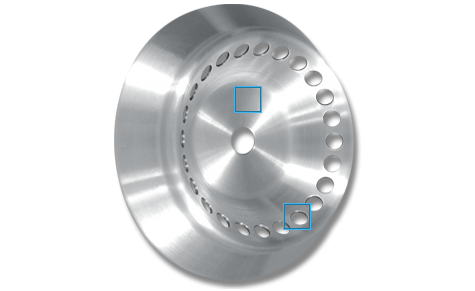

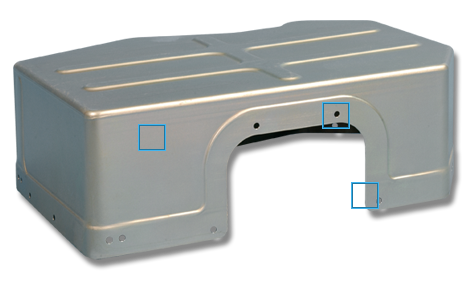

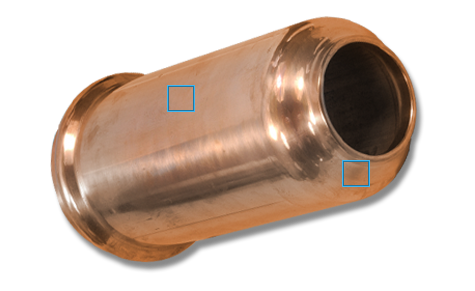

LOWER COSTS AND HIGHER QUALITY

We perform most secondary operations at our facility in Mountainside, New Jersey, resulting in higher quality and lower costs.

- Deep draw, hydroforming, and metal forming

- CNC Machining, piercing, blanking, forming, heat treating, spot welding, Heliarc® welding, assembly, painting (wet and powder), anodizing, iriditing and others

- Aluminum, stainless steel, nickel, brass, copper, tabouret, Hastelloy®, Inconel®, mu-metal, Monel®, steel, bronze and exotic alloys