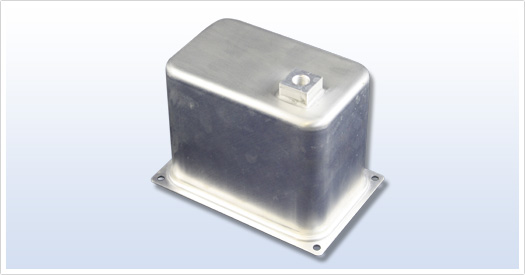

Dip Brazed and Deep Drawn Medical Battery Housing

Dip Brazed and Deep Drawn Medical Battery Housing

This aluminum battery housing was manufactured using CNC machining. This medical part was dip brazed and has a clear anodized coating.

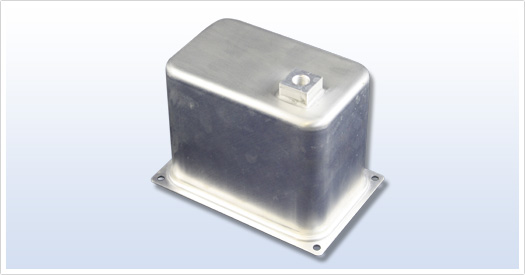

Dip Brazed and Deep Drawn Medical Battery Housing

Dip Brazed and Deep Drawn Medical Battery Housing

This aluminum battery housing was manufactured using CNC machining. This medical part was dip brazed and has a clear anodized coating.

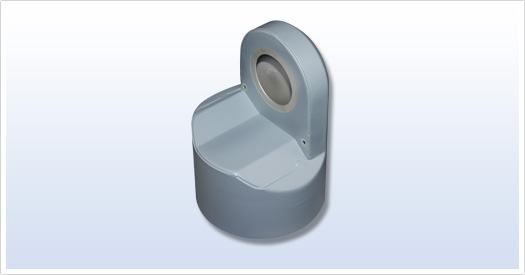

Deep Drawn and Hydroformed Aluminum Optical Housing

Deep Drawn and Hydroformed Aluminum Optical Housing

This aluminum optical housing has been constructed from three separate parts, which Amalco hydroformed, deep drew, and assembled. It is RoHS compliant — meaning that it adheres to Restriction of Hazardous Substances regulations. This piece has also been iridited and painted. Its dimensions are 5″ x 8″.

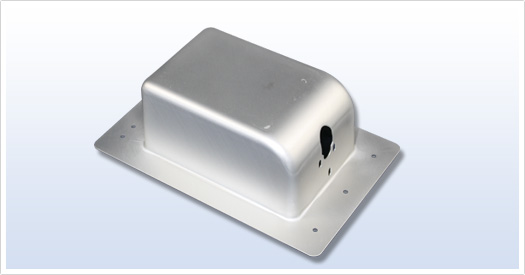

Deep Drawn and Hydroformed Aluminum Electrical Cover

Deep Drawn and Hydroformed Aluminum Electrical Cover

This is an aluminum electrical cover hydroformed and deep drawn for use in industrial applications. The holes have been CNC machined with an RoHS-compliant iridite finish. RoHS means that it adheres to Restriction of Hazardous Substances regulations. The dimensions of this piece are 5″ x 10″ x 4″.

Deep Drawn, Hydroformed and Dip Brazed Aluminum Starter Housing

Deep Drawn, Hydroformed and Dip Brazed Aluminum Starter Housing

This aluminum starter housing was manufactured from sheet metal using CNC machining and a combination of hydroforming and deep drawing processes. Its been spot welded and dip brazed, and its dimensions are 8″ x 10″ x 4″.

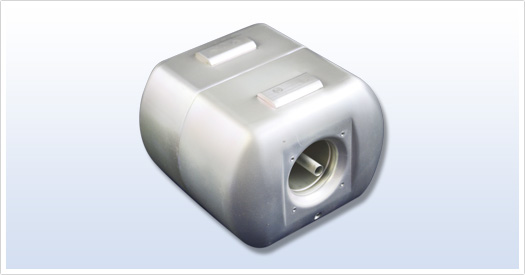

Dip Brazed and Deep Drawn Missile Battery Housing

Dip Brazed and Deep Drawn Missile Battery Housing

This missile battery housing was manufactured using CNC machining. This military part was dip brazed and finished in iridited coating.

Dip Brazed and Deep Drawn 8 Part Assembly with Iridite Finish

Dip Brazed and Deep Drawn 8 Part Assembly with Iridite Finish

The rounded 8 part assembly is dip brazed for specialized military use. The aluminum parts were sealed with an iridite coating.

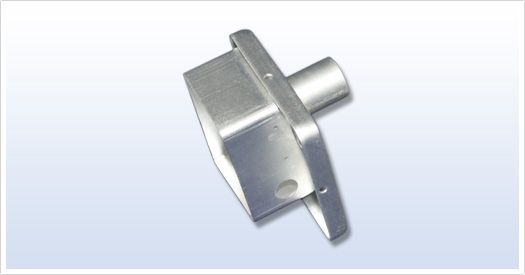

Dip Brazed and Deep Drawn Aluminum Part

Dip Brazed and Deep Drawn Aluminum Part

The rounded 8 part assembly is dip brazed for specialized military use. The aluminum parts were sealed with an iridite coating.

Deep Drawn Aluminum Radar Housing

Deep Drawn Aluminum Radar Housing

This is a deep drawn aluminum radar housing made by Amalco to precise military specifications. The flange on this unit has been welded. The dimensions of the unit are 4″ x 10″ x 7″.

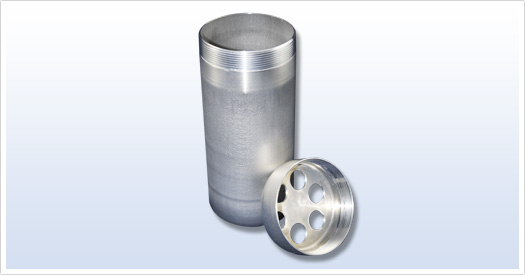

Deep Drawn Aluminum Power Supply

Deep Drawn Aluminum Power Supply

This is a deep drawn aluminum power supply unit for use in communication applications. The holes have been pierced, and the threads were CNC machined. The entire unit has been anodized. Its dimensions are 4″ x 8″.

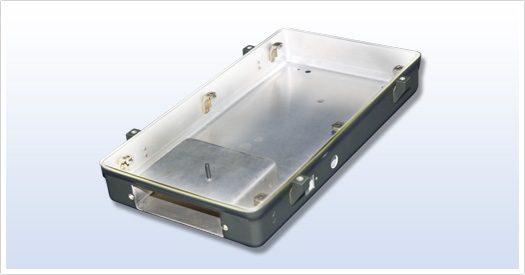

Deep Drawn and Dip Brazed Aluminum Arming Box

Deep Drawn and Dip Brazed Aluminum Arming Box

This is a deep drawn aluminum arming box made by Amalco for military applications. It has been spot welded and includes riveted bracket and a dip brazed box inside the housing. Its dimensions are 8″ x 14″ x 3″.