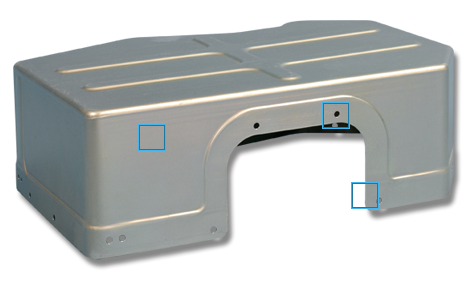

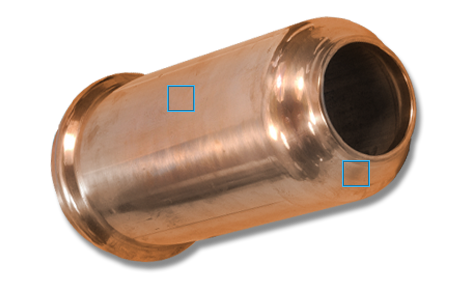

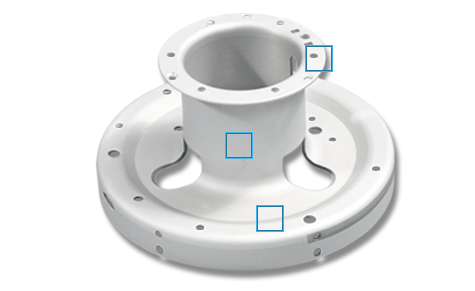

Design and Engineering Support for Hydroforming and Deep Drawn Metal

With 110 years and four generations of experience, Amalco offers design and engineering support for customers in need of deep drawn and hydroformed metal parts. Our team is ready to help you solve design challenges and answer your hydroforming process and deep drawing process questions. If you are new to metal forming and fabrication, Professor Metal is here help you get started.

SIZES

SIZES MATERIALS

MATERIALS SECONDARY OPERATIONS

SECONDARY OPERATIONS

Quality System (Conforms to MIL-I-45208)

Quality System (Conforms to MIL-I-45208)